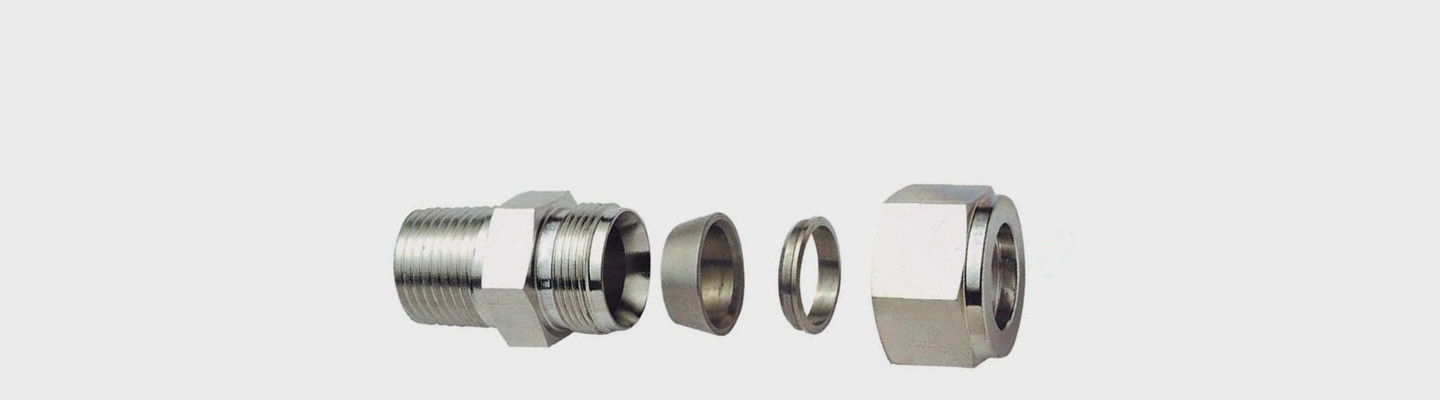

compresssion fitting

Sleeve type pipe joint is composed of three parts: a joint body, card sets, nut. When the card sleeve and the nut is sheathed on the steel tube is inserted into the joint body, when the nut is screwed, card sets the outer side of the front end and the joint bodyconical surface, the inner edge evenly bite into the seamless steel pipe, form effective seal.

24 °cone type W column end according to DIN 3861 standard. Card sets of the application of double card set.

Usually a joint body and a nut galvanized surface treatment. Joint for working pressure up to 63MPa, maximum diameter of42mmseamless steel pipe.

Card sets of joints assembly

Installation

1saw under a suitable length of seamless steel pipe, the port burr removal. The pipe end to the vertical axis and the angle tolerance, not more than 0.5 deg. If the pipes need to be bent, from the pipe end to the bending part of the straight section length cannot be less than three times the length of the nut.

The 2nuts and card sleeve on the seamless steel tube. Pay attention to the nut and ferrule orientation, not anti-loaded.

3 in preassembled connector thread and card sets with lubricating oil, the pipe is inserted into the joint body, ( the pipe must beinserted in the end by hand tightening the nut ).

Tighten nut until4card sets of stuck pipe, this turning point through the tightening torque increases feel ( pressure points).

5pressure points, then the nut tightening the 1/2ring.

6 will be preassembled connector body removed, check the card edge embedding, visible protrusions to fill the card sleeve endspace. Card sleeve can be rotated slightly, but not axial passage.

The 7final installation, the installation of the threaded joint body coated with oil, nut matched with the screw to be sensed by thetightening force is increased. Then tighten the 1/2ring installed.

The repeating installation

All card sets of joints can be repeated reloading, but to ensure that no damage and clean parts.

The 1pipe is inserted into the joint body until the card sleeve affixed immediately head body cone, hand tighten nut.

2 use wrench to tighten the nut, until the tightening torque increases rapidly, and then tighten the 1/4to 1/2ring can be.

Check

Detachable pipe inspection properly rigged: card sleeve end pipe should have even a slight bulge. Card sleeve can slide back and forth, but allow a slight rotation.

Leakage causes

1tube was inserted in the end.

The 2nuts are not tightened.

3 pipes or tubes round appearance scratch.

The 4tube is too hard.

Sleeve type pipe joint is composed of three parts: a joint body, card sets, nut. When the card sleeve and the nut is sheathed on the steel tube is inserted into the joint body, when the nut is screwed, card sets the outer side of the front end and the joint bodyconical surface, the inner edge evenly bite into the seamless steel pipe, form effective seal.