Carbon steel

First, the definition

Mainly refers to the carbon mass fraction is less than 2.11% without containing deliberately added alloying elements of steel.Sometimes referred to as carbon steel or carbon steel.

Carbon steel, also known as carbon steel, refers to the carbon content of Wc is less than 2.11% of the iron-carbon alloy.

Carbon steel in addition to carbon generally also contain a small amount of silicon, manganese, sulfur, phosphorus.

Second, classification

(1) by end-use can be carbon steel into carbon structural steel, carbon tool steel and easy cutting steel into three categories, carbon structural steel is divided into the project to build the two kinds of structural steel on steel and machinery manufacturing;

(2) can be divided into open-hearth steel smelting, converter steel;

(3) the deoxidation method can be divided into the boiling steel (F), killed steel (Z), semi-killed steel (b), and special killed steel (TZ);

(4) the carbon content can be carbon steel is divided into low-carbon steel (WC ≤ 0.25%), medium carbon steel (WC0.25% -0.6%) and high-carbon steel (WC> 0.6%);

(5) the quality of steel, carbon steel is divided into ordinary carbon steel (phosphorus, sulfur, higher), high-quality carbon steel (phosphorus, sulfur, low) and high quality steel (phosphorus, sulfur, lower ) and super high quality steel.

Description: general carbon steel carbon content higher the greater the hardness, the higher the intensity, but the ductility is low.

Third, the common carbon steel

A. Carbon structural steel

Grade: the case of Q235-A · F, that σs ≥ 235MPa

Grade annotation: Q is the yield strength of A quality grade (ABCD four), F boiling steel

Features: low prices, excellent process performance (such as weldability and cold formability).

Applications: general engineering structures and mechanical parts. Q235 can produce bolts, nuts, pins, hooks, and less important mechanical parts and building structures in steel, steel, steel and other

Two. Quality carbon structural steel

Grade: cases 45,65 Mn, 08F

Grade Note: Direct, said Wan scores of the metal carbon content

Applications: non-alloy steel for manufacture of important mechanical parts, are generally required to be heat-treated after use.

Commonly used in steel and uses:

08F, the carbon mass fraction is low, good plasticity, low strength, for stamping parts such as automotive and instrumentation enclosures;

20, good ductility and weldability, strength less demanding parts and carburizing parts, such as the hood, welding the small axis of the container, nuts, washers and carburized gears, etc.;

45,40 Mn, the mechanical properties after quenching and tempering for the force of mechanical parts, such as gears, connecting rods, machine tool spindle;

60, 65 Mn steel has higher strength; used in the manufacture of a variety of spring, motorcycle rim, low-speed wheel.

3. Carbon tool steel

Grade: such as T12 Steel said Wc = 1.2% carbon tool steel.

Grade annotation: T plus metal carbon content thousandths

Characteristics: the case of the eutectoid steel and over-eutectoid steel, strength, high hardness, good wear resistance for the manufacture of a variety of low-speed cutting tools.

Commonly used in steel and uses:

T7, T8: production withstand certain impact requirements of the toughness of the parts. Such as a sledge-hammer, punches, chisels, woodworking tools, scissors

T9, T10, T11: to create the impact of small tools require high hardness and high wear resistance. Such as taps, drills, dies, hand saw blade

T12, T13: production of non-impact tools. Files, scrapers, razor, measuring

4. Cast steel

Grade: For example, ZG200-400, said σs of ≥ 200MPa, σb ≥ 400MPa cast steel.

Performance: the casting properties than cast iron, but the mechanical properties than cast iron;

Application: mainly used in the manufacture of complex shape, and mechanical performance requirements, very difficult in the process, forging and other methods of forming the more important mechanical parts such as car gearbox shell, rolling stock coupler and coupling. Four impurity elements in the performance of carbon steel

1, manganese

About 0.25% to 0.80%. Solid solution strengthening; clear of FeO to reduce the brittleness of the steel; sulfide synthesis of MnS can reduce the harmful effects of sulfur. Useful.

2, silicon

About 0.10% to 0.40%, the solid solution strengthening; In addition to the adverse effects of FeO on steel quality and useful.

3, sulfur

FeS and Fe to form low melting point eutectic (melting point 985 ° C) led to the steel brittle and cracking in the 1000 ~ 1250 ℃ thermal processing, "thermal embrittlement". Harmful.

4, phosphorus

Strength, hardness, but lower ductility and toughness, "cold short". Harmful.

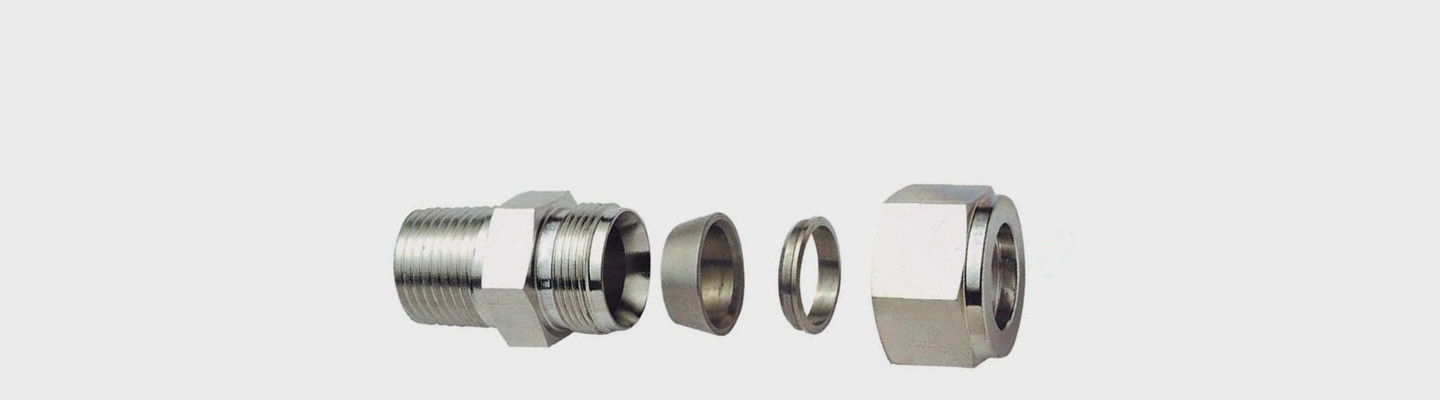

ferrule - Carbon steel

time:2017-03-07 14:47:48 hits:second

prev:ferrule - Stainless steel(3)

next:Welded pipe joints