Thread briefly

(English name: screw the thread): The system in the mother on the surface of cylindrical or conical spiral linear, with a specific cross-section of a continuous convex part. Threads according to their parent shape is divided into a cylindrical thread and taper thread; according to their location in its mother's body is divided into the external thread, internal thread, according to the sectional shape (tooth type) is divided into triangular thread, rectangular thread, trapezoidal thread, zig-zag thread and other special shape of the thread, triangular thread is mainly used for connection, rectangular, trapezoidal and zigzag thread is mainly used for transmission; the direction of the helix into a left hand thread and right hand thread, usually with a right hand thread; the number of points according to the helix single threaded, wire thread and multi-line thread; connection with the mostly single-line, drive the adoption of two-lane or multi-line; divided into coarse thread and fine thread according to the size of the teeth, according to the occasions and functions can be divided into the fastening thread, pipe thread, transmission thread, dedicated thread.

Thread classification

Threaded according to the sectional shape (tooth type) into thread triangles, rectangles, thread, trapezoid thread and the zigzag thread. Triangular thread is mainly used for the connection (see the thread connection), rectangular, trapezoidal and zigzag thread is mainly used for transmission. Thread distribution of the surface outside the mother called the external thread, called the internal thread in the mother's body surface. The threads formed in the cylindrical mother called cylindrical threaded, the threads formed on the conical mother called conical thread. Thread at the direction of the helix is divided into two left-handed and right, usually with a right hand thread. Thread can be divided into the single line and multi-line connection with the mostly single-line; for drive requirements into l fast or high efficiency, the use of two-lane or multi-line, but generally not more than four lines.

The main parameters of the cylindrical threaded outer diameter (d), inner diameter (d1) in diameter (d2), pitch (t), the line number (n), lead (s = nt), angle (λ) and conodonts angle (α). In addition to the pipe thread to tube inner diameter, nominal diameter, the rest of the thread to the outside diameter of the nominal diameter.

The thread angle is less than the friction angle of the screw pairs, loose turn in the role of the axial force, known as the self-locking, the transmission efficiency is low.

Cylindrical thread, triangular thread self-locking performance. It was divided into two kinds of coarse and fine pitch, generally connected with coarse thread. Small fine tooth pitch or angle is small, better self-locking performance, thin-walled tubes commonly used in small parts, vibration or variable load connected, as well as fine-tuning device. Close connection of the pipe threads for pipe. High efficiency rectangular thread, but not polished, and the internal and external threaded together centering is more difficult, Guchang trapezoidal thread instead. Thread of the serrated side close to the rectangular straight edge, and more for under one-way axial force.

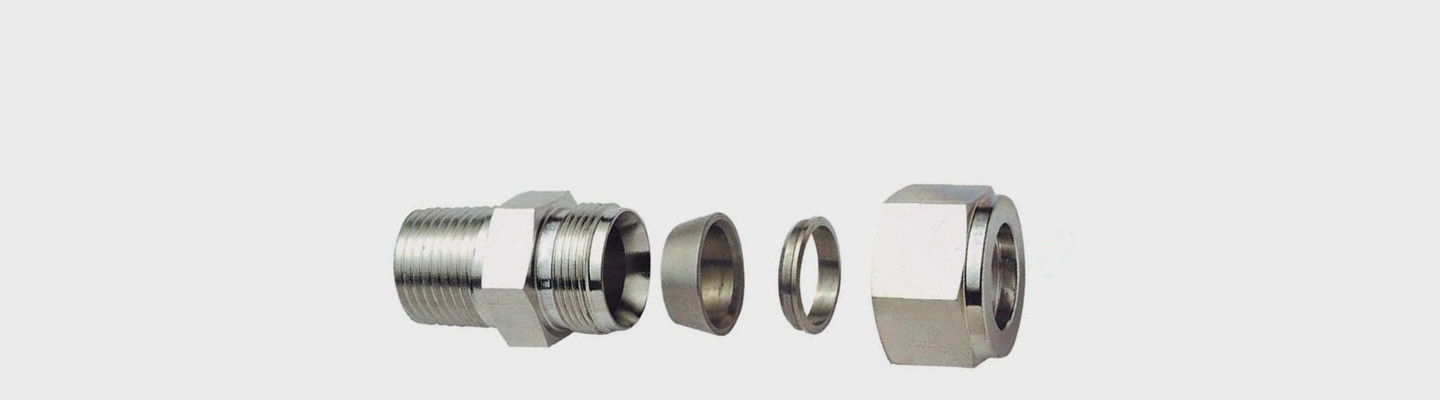

The teeth of the tapered thread type for the triangle, depends mainly on the deformation of the teeth to ensure the tightness of the screw pairs, used for pipe fittings.

Thread measurement

1, the general standard thread using a thread ring or plug gauge to measure.

Thread measurement

2, thread micrometer is used to measure the pitch diameter. The method can also be the amount of needle measuring the pitch diameter, said the three-pin Method.

3, thick tooth vernier caliper used to measure the diameter tooth thickness trapezoidal thread and worm pitch diameter tooth thickness.

Other parameter measurement using a special measuring tools and equipment.

Thread painting

In mechanical drawing, threaded and threaded fasteners view mapping is more complicated. To improve mapping efficiency, usually require painting (see photo). International standards ISO and mechanical drawing standards provides: thread the top with a thick solid line

The painting of the threads and threaded fasteners

Said that the bottom teeth with a thin solid line, in view of the projection plane perpendicular to the axis of the thread, thin solid line painted on the teeth at the end of 3/4 circle, thread termination boundary of the thick solid line. The thread tooth type, diameter, pitch in the label size using threaded code indicated. In the cutaway view of the assembly drawing, the provisions of threaded fasteners according to not cutting drawing, and threaded fasteners provisions to simplify the drawing, a group of fasteners such as hex head bolts, hex nuts and washers may Figure painting in the drawing.

The main geometric parameters of the cylindrical thread

Imaginary cylinder diameter, the ① outer diameter (large diameter), coincides with the end of the top of external thread or the thread. Thread nominal diameter, that is, a large diameter.

② ID (trail), and the outer end of the thread teeth or thread the top coincides with the diameter of the imaginary cylinder.

③ diameter, bus by tooth type bump and groove of both width equal to the imaginary cylinder diameter.

Corresponding axial distance between two points the ④ pitch, the adjacent teeth in the diameter line.

(5) lead, the same spiral line adjacent teeth corresponds to the axial distance between two points in the diameter line.

The ⑥ tooth type angle, the screw threads adjacent to the angle between the two flank.

The angle between the helix the the ⑦ thread angle, diameter cylindrical tangent and the plane perpendicular to the thread axis.

⑧ working height, and two matching screw threads on the overlap part in the direction perpendicular to the thread axis distance.Thread nominal diameter in addition to tube threaded pipe inner diameter for the nominal diameter, the rest to the outside diameter of the nominal diameter. The thread has been standardized, there are two kinds of metric (metric) and imperial. The international standard metric, China has also adopted the metric system.

Cylindrical thread, triangular thread self-locking performance. It was divided into two kinds of coarse and fine pitch, generally connected with coarse thread. Small fine tooth pitch or angle is small, better self-locking performance, thin-walled tubes commonly used in small parts, vibration or variable load connected, as well as fine-tuning device. Close connection of the pipe threads for pipe. High efficiency rectangular thread, but not polished, and the internal and external threaded together centering is more difficult, Guchang trapezoidal thread instead. Thread of the serrated side close to the rectangular straight edge, and more for under one-way axial force.

The teeth of the tapered thread type for the triangle, depends mainly on the deformation of the teeth to ensure the tightness of the screw pairs, used for pipe fittings.

screw thread

time:2017-03-07 14:52:20 hits:second

prev:Seamless Steel Tube national standard specifications table